The Columbia Group provides proven, cost-effective Operational Logistics support. Our approach is nested with Integrated Logistics Support (ILS). The goal of the ILS system is to create enduring systems, which ease costs by requiring less support and eventually increasing return on investment. Our Operational Logistics experience includes support provided in each of the 10 elements of logistics:

- Computer Resources Support

- Design Influence/Interface

- Facilities

- Maintenance Planning

- Manpower and Personnel

- Packaging, Handling, Storage, and Transportation (PHST)

- Supply Support

- Support Equipment

- Technical Data

- Training and Training Support

Past Performance Indicates Future Success

Our proven best practices have helped our past and current customers save both time and money. Our support has included:

- IMCOM-recognized Army-wide Central Issue Facility (CIF) model

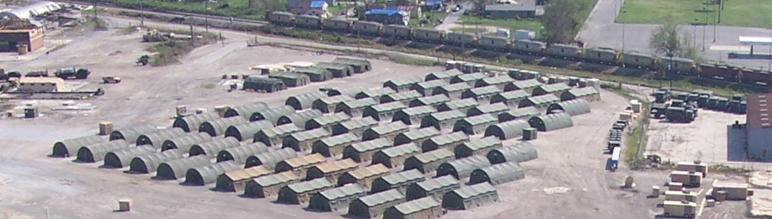

- AMC-recognized model container management operation

- Design, development, and implementation of a time and cost-saving detonating cord measuring device adopted into the Army Peculiar Equipment Catalog

- Design, development, and implementation of the “kitting” concept at one of our CIF operations, cutting Soldiers’ wait time in half